SEAT CUTTING TIPS

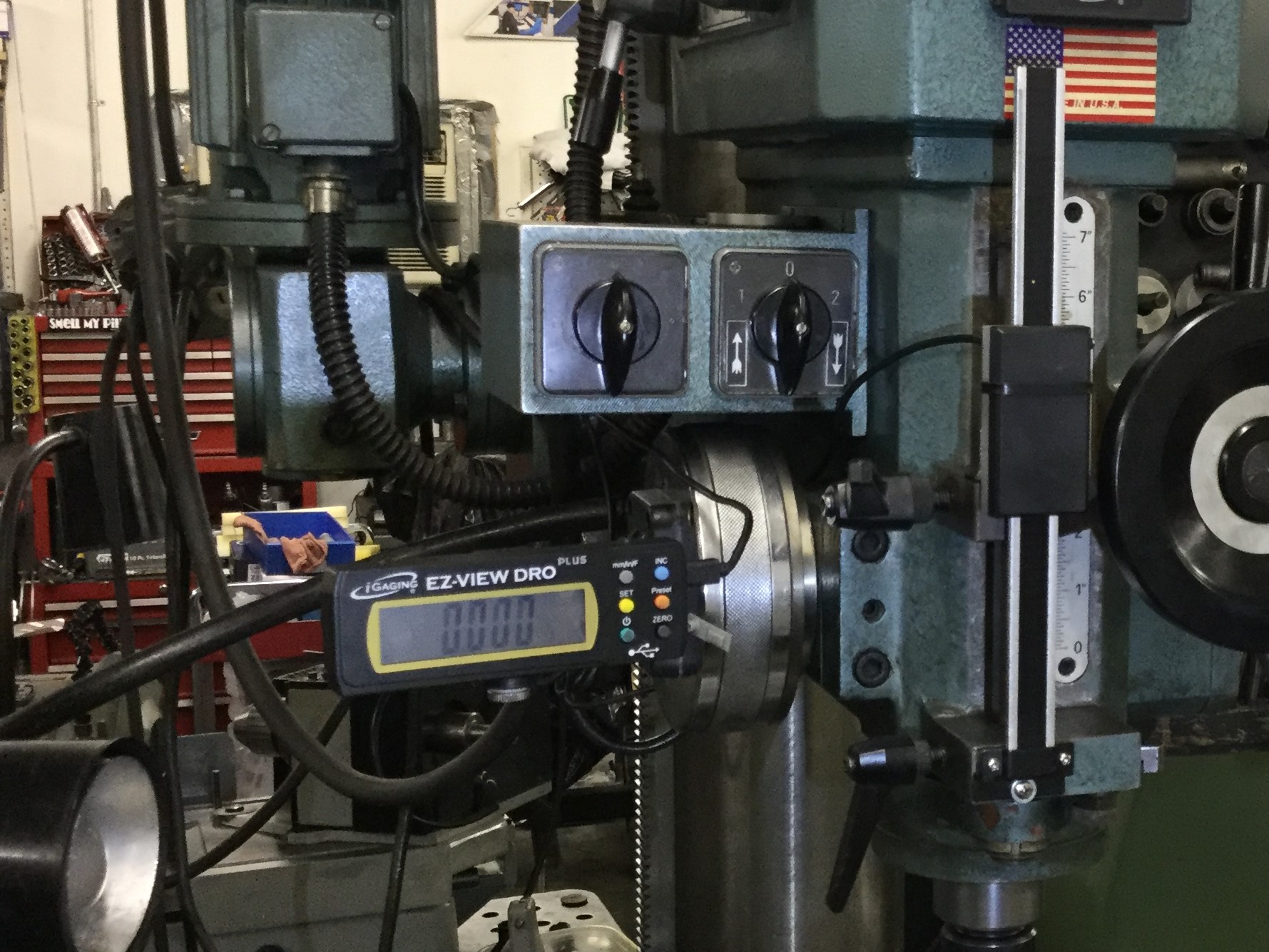

When cutting in valve seats with a single, multi angle blade, especially new ones, try to do the least amount of work with the profile tool as possible. For instance, if the bottom angle is 75°, cut as much of the seat away as you can with that single blade and then come in with your seat profile blade and finish the remaining upper angles. It may take a few cuts back and forth to get the height established, but then zero your end stop for the rest of them. It goes real fast after the first one. An inexpensive digital read out (DRO) on my quill has really helped the accuracy and speed on multiple tool setups. You’ll find that you get much less run out and chatter. Also, you get longer tool life on the critical blade. I prefer to touch the seat angle with a stone to finish.

Ron Flood

Cedar Machine

April, 2018