IN HOUSING SHAFT REPAIR

Let’s say you need to repair damaged threads on the impeller end of a pump or turbo shaft, which is recessed in the housing, and maybe even mushroomed by a hammer-happy tech. You cannot remove the shaft from the housing because of the mushroomed end or maybe you can’t get new bearings or seals; and you don’t want to disassemble it. You need to center the shaft in the lathe, but obviously cannot center off damaged threads and no bearing surfaces are available without disassembly. Disassembly and re-assembly can add extra time to the job.

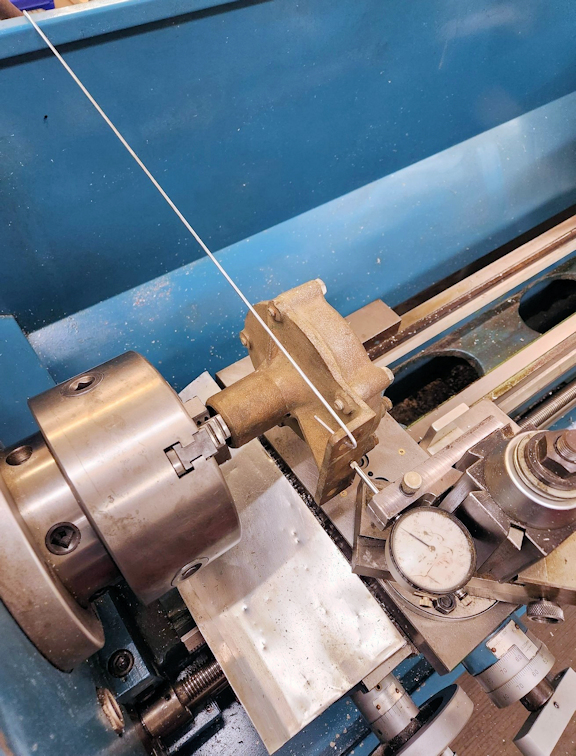

You can center the shaft and machine it as an assembly.

I’ve used this time saving method to successfully repair dozens of generators and alternators, turbos, and industrial pumps as shown in the picture. It can be a real money-maker.

Tom Nichols

Automotive Machine & Supply, Inc.

Joshua, TX

JUNE, 2023