ENGINE BEARINGS – FRICTION AND PRE-LUBRICATION

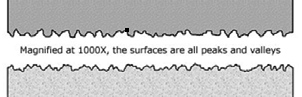

Overcoming friction is essential to successful bearing service. In order to understand friction we must take a close-up look at a “smooth” surface. If we were to take a cross-section of a polished piece of metal, we would see that even a ground and polished surface has peaks and valleys (If magnified, picture 2 files rubbing together). Measuring these peaks and valleys with a precision electronic instrument is how surface finish is determined. When two surfaces come together, the peaks make contact. Under load, the peaks tend to weld together. This is often called “micro-welding”. Sliding the mating surfaces across each other requires that these tiny welds be broken apart. This is friction. As the peaks are torn apart heat is created and tiny particles break off causing what we commonly refer to as wear. With very few exceptions, engine bearings rely on hydrodynamic lubrication for successful performance. What that means is, in operation the shaft floats on a thin film of oil. This is what keeps friction and wear to a minimum. Thickness of the oil film depends on a number of variables within the engine such as load, speed and oil viscosity. Oil film thickness should not be confused with clearance, which is the space between the shaft and bearing. Although the entire clearance space may be filled with oil, the shaft is forced off center by engine loads. This causes the shaft to operate very close to the bearing on one side of the clearance space. Generally speaking minimum oil film thicknesses in this loaded area of the bearing are typically in the range of only .0001” to .0002”. Even though these minimum oil film thicknesses are very small, engine bearings can have an almost unlimited life if proper operating conditions are established at assembly and maintained throughout the engine’s service life. The engine’s oil film is generated by shaft rotation. At rest the shaft and bearing are in contact. On start-up the shaft rubs the bearing briefly. Running, the shaft pulls oil from the clearance space into the wedge shaped area between the shaft and bearing. The oil wedge lifts the shaft away from the bearing and supports it during engine operation. The force exerted by the oil wedge must be sufficient to offset the load applied by the engine or the oil film will collapse resulting in contact. Because oil must be present in the bearing clearance space in order for the shaft to build an oil film, pre-lubricating an engine before initial start-up is extremely important. Even though everything inside the engine was coated with oil at assembly, oil can be thrown off rather quickly once the crankshaft starts spinning. Actually pumping oil through the engine’s oil galleries is the only effective way to pre-lubricate the engine. This can be done on some engines by actually driving the oil pump with an old distributor shaft or oil pump priming tool in an electric drill. Where this is not feasible, supplying pressurized oil from an external source is the best way. Attach a hose from the oil source to the engine’s main oil gallery where the oil pressure-sending unit mounts. Pre-lubing in this way will prime the pump and filters and fill all oil passages. Having explained a little about friction and wear and how a bearing’s oil film is formed, it is easy to see that oil film thickness and surface roughness are interrelated. Rougher surfaces demand thicker oil films to prevent friction and wear. Obviously, if the surface roughness of the shaft exceeds the oil film thickness, wear will result. Similarly, conditions which cause misalignment between shaft and bearing surfaces such as taper, barrel shape or hour glass in journals or housing will negatively affect the maintenance of an adequate oil film across the entire bearing surface. Modern bearing designs have also eliminated features like holes and grooves from the loaded areas of bearings because they tend to break-up the oil film and reduce the margin for operating safety.

Engine Pro Technical Committee

with thanks to Mahle Aftermarket Inc.

July, 2014