CNC FEED & FEED CHART

Shops with CNC mills often need to do a “quick” task, such as drilling a few holes, or taking a cut along one axis, etc. this tip discusses 3 methods to do so.

- Most machines have a pendant or hand wheels the operator can use to move the tool in one axis. However, this manual motion is often jerky, or too slow or too fast, resulting in broken tools, or a poor finish on the part.

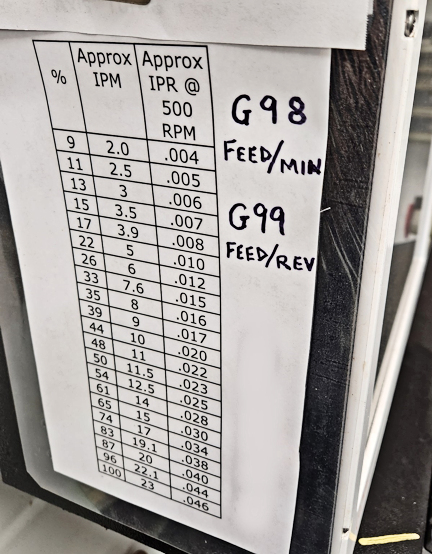

- Another option is using the feed-% override knob and jog buttons. Turn the feed rate % down and press the axis’ jog button to make a smoother, more controlled cut. To help our employees choose where to set the feed rate %, I attached the chart below to the side of the controls. I obtained the chart’s data by simply timing several feed rate-% settings over 10″ of motion:For example, from the chart, setting the feed rate over-ride at 22%, and pressing the X-axis jog button will move the tool along the X-axis, at 5 Inches/Minute (IPM) with the machine in G98 mode. Note: some machines may require a separate column(s) for the Z-axis rates (drilling/boring moves).

- An even better way to achieve single or combined axis motion, for doing quick jobs, is to learn a few basic G-codes, and use MDI (Manual Data Input) to type/enter simple G-code moves. I strongly suggest operators study the machine’s manual and learn a few very basic M&G codes, such as M3, M5, M8, M9, G00, G01, G90, G91, G98, G99, S, F. Then practice “cutting air”. Also study how tool offsets work and their related G-codes.

- *G90 G98 G00 X0 Y0 Z15-Sets ‘absolute’ position mode; sets IPM feed mode; sets full rapid feed mode; moves tool, at full rapid feed rate, to the current established X0, Y0, Z15 locations.

- *M3 S500-Starts the spindle turning CW at 500 rpm,

- *G91 G98 G01 X2 Y-1 F12-Sets the ‘incremental’ positioning mode; sets IPM feed mode; sets feed-rate mode, incrementally moves the tool along X axis +2″ and along Y axis -1″, at 12 IPM.

- *G90 G98 G01 Z5 F4-Sets ‘absolute’ positioning mode; sets IPM feed rate mode; sets feed-rate mode, ‘absolutely’ moves tool along the Z axis to +5″, at 4 IPM.

After some experience with these simple moves, operators should begin to understand and learn additional simple M&G-code, their machine’s default and modal codes, so they can quickly and easily use MDI to do simple tasks.

Tom Nichols

Automotive Machine & Supply, Inc

Joshua, TX

SEPTEMBER, 2023