Main Cap Tech

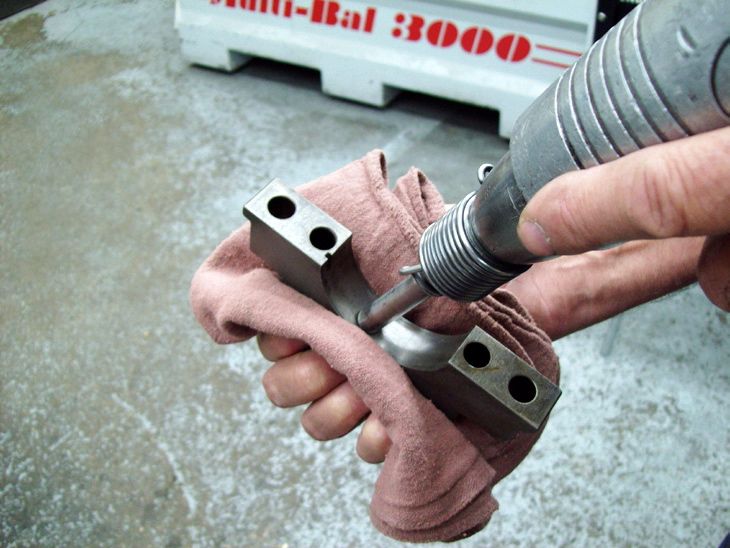

One of the main problems with blocks that need to be align-bored is the lack of squish between the main cap and the block. What I am referring to is the interference fit between the cap and main register that holds the cap in alignment, and is the reason a light tap is needed to seat the cap. If the caps do not fit tight, the crank will not be held as solidly as it was intended, and also results in inconsistent bearing clearances. This lack of squish is reason enough to align bore a block, even if the engine had no previous crankshaft problems, to avoid a future crank issue. (Four bolt small block Chevys are notorious for having loose caps.) The caps do not fit tight because they have shrunk due to stress. This stress causes them to pull away from the main registers. I have seen some attempted “fixes” where someone has center punched or used a chisel on the block to try to tighten the cap. This does not address the stress issue, and also moves the caps with regards to the centerline of the block. The proper way to restore squish is to remove the stress in the cap, which is where the problem lies. We do this by peening the cap using an air hammer with a rounded off broken valve guide driver (approx. 1/2′′). Work the under- side of the cap (where the bearing goes) in the center 1′′ to 1 1/2′′. The peening action of the air hammer will relieve the stress in the cap, and the sides will spread to their original position. Make sure you do this before you cut the caps, to keep them flat. By using this method you can actually control the amount of squish the caps will have. Yes it will leave some marks on the cap, but they will clean up with the align bore. By using this method the caps fit tight in the registers, the stress has been removed from the caps and the original centerline of the engine can be maintained by align boring.

Stacy Redmond

Grawmondbecks Competition Engines

Mason City, IA

November, 2014