LET’S GET VISUAL

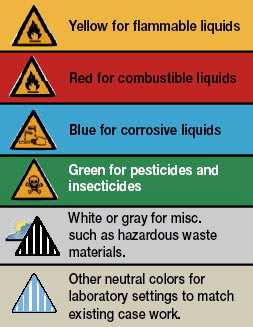

”Visuals” not only help eliminate waste, but can have additional positive impact on a shop’s operation, safety and cost. *Safety glasses (with side shields) should be mandatory in all shop areas; not just machining, grinding, welding, etc.. This can reduce insurance costs and avoid OSHA fines. *Color coded (safety yellow/red) storage cabinets for paints and any flammable materials. *Color coded (safety yellow) defining walkways and machine guarded areas. *Machine guarding around any belt/pulley and/or moving machine part should not allow more than 1/4” access to the moving machine part, and in the case of pedestal grinders 1/8”gap (max.) be- tween the wheel and work rest. Note: OSHA has now been given greater power to level increased fines via (unannounced) visits no matter what size shop. All it takes is one (disgruntled) employee to call in a complaint and you can expect a visit – I have seen this happen in a friend’s fab shop resulting in a $75,000.00 fine.

Jim Kovach

Kovach & Assoc.,Performance Engine Building

Parma, OH

February, 2016