IN SHOP CAMSHAFT ANALYSIS

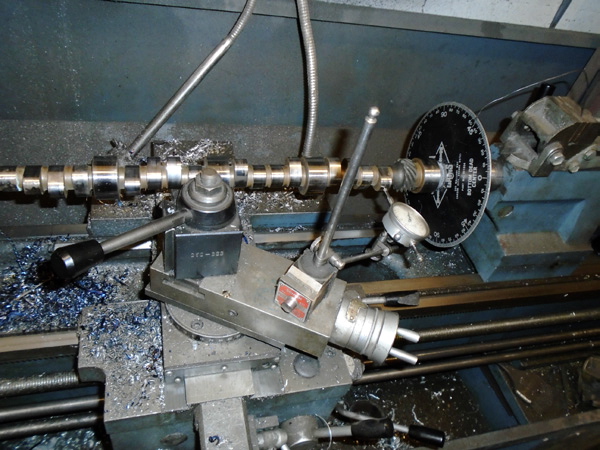

Our shop has had a cam analyzer for over 28 years, so I had forgotten how we checked and identified cams in the past. Recently I was asked by another shop how to verify which of three customer supplied cams to install in the customer’s engine. The previous shop that had built his engines had ground the name and ID numbers off of all three camshafts! – I told him to install the cam in his lathe on centers, with a degree wheel on the tailstock end and to put a pointer on the degree wheel as well. A small piece of heater hose over the tail- stock center will hold the degree wheel up against the end of the cam. I then instructed him to put a magnetic base dial indicator on the lathe’s cross slide and set it up against a lobe. We zeroed the pointer, then the dial indicator and rotated the cam until the indicator read .050”. At that time we set the degree wheel to zero without moving the cam. We then rotated the cam over the lobe until the indicator again read .050” and read the number, when multiplied by two, this number is the duration at .050 for that lobe. Do each lobe a few times until you get repeat- able results, then move on to that cylinder’s other lobe and do the same thing. Then move to the lobe’s top and zero the indicator. go .050 down one side of the lobe and zero the degree wheel, then go up over the top of the lobe to .050 down the other side of the same lobe. Read the degree difference, divide by two and set the degree wheel to zero. Move the indicator to that cylinder’s other lobe, and zero the indicator again at the lobes top. Go down one side .050 and record the number, then go down the other side of the lobe .050 and record that number. Again divide by two, subtract the one number from the other number again, and that is your lobe center in degrees. Play with a known cam until you get the hang of things and can get good results. You may be off a few degrees one way or another, but with care you will get close enough to identify an unknown cam. – The lobe lift is easily found. For that number just zero the indicator on the base circle, then rotate the cam to the highest number, and that will be the lobe lift. Multiply that by the rocker ratio and you have the lift at the valve. – We will not buy any cams from smaller companies who play fast and loose with what they sell. Some buy old, worn lobe masters from the bigger companies, and mark these cams with smaller .050 numbers so that their cam will make the same power as a quicker ramped newer design cam with less duration. – Others may advertise that they grind more powerful cams, but in many cases its because the lobes are bigger than advertised! If you set up the valve springs with enough clearance to coil bind, and the lobe is bigger than advertised, you may have problems! We check all customer supplied cams, its good to know what everyone grinds, and whether we would ever recommend those products. – Any shop that grinds the numbers off of a cam to keep the customer coming back to his shop may be in for a surprise. Nearly every time we ID an unknown cam for a new customer, he becomes OUR customer. We do the ID cheaply enough to show people that there is more than one way to run a business.

Timm Jurinc

Tuf-Enuf Auto & Marine Performance

Avondale,AZ.

September, 2016